Solutions

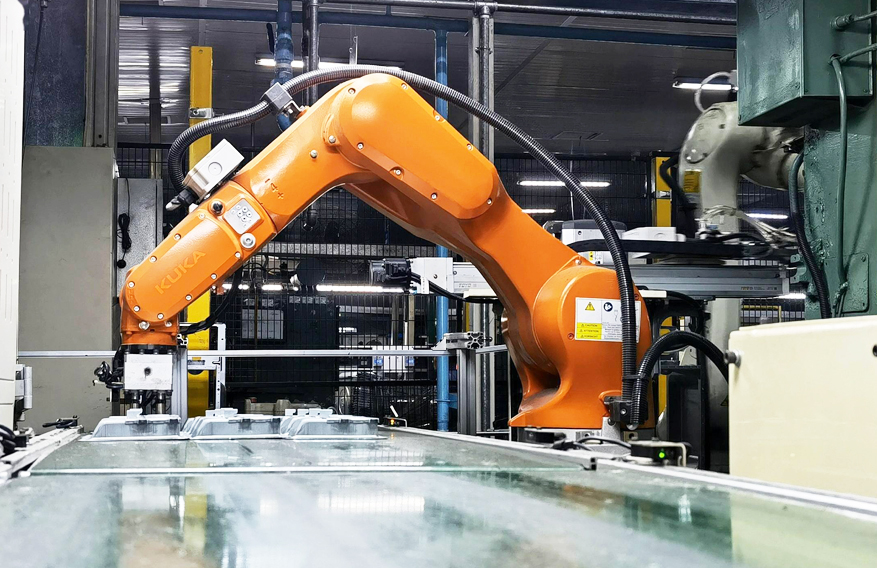

Automatic production line refers to a form of production organization in which the product process is realized by an automated machine system. It is formed on the basis of the further development of the continuous assembly line. Its characteristics are: the processing object is automatically transferred from one machine tool to another machine tool, and the machine tool automatically performs processing, loading and unloading, inspection, etc.; the task of the worker is only to adjust, supervise and manage the automatic line, and does not participate in direct operation; all The machinery and equipment all operate in a unified rhythm, and the production process is highly continuous.

Automatic production line refers to a form of production organization in which the product process is realized by an automated machine system. It is formed on the basis of the further development of the continuous assembly line.Products produced by automatic lines should have a large enough output; product design and technology should be advanced, stable and reliable, and remain basically unchanged for a long time. The use of automatic lines in mass production can increase labor productivity, stabilize and improve product quality, improve labor conditions, reduce production floor space, reduce production costs, shorten production cycles, ensure production balance, and have significant economic benefits. The automatic production line is the process of automatically operating or controlling according to the prescribed procedures or instructions without human intervention, and its goal is "stable, accurate and fast". Automation technology is widely used in industry, agriculture, military, scientific research, transportation, commerce, medical care, services and households. The use of automatic production lines can not only liberate people from heavy physical labor, some mental work, and harsh and dangerous working environments, but also expand human organ functions, greatly improve labor productivity, and enhance human ability to understand and transform the world.

With the development of control technology, computer, communication, network and other technologies, the field of information interaction and communication is rapidly covering all levels from the field equipment level of the factory to the control and management levels. Industrial control machine system generally refers to the general term of automation technology tools (including automatic measuring instruments and control devices) that measure and control industrial production processes and their electromechanical equipment and process equipment. Agrade joins hands with a well-known domestic manufacturer to use Internet of Things technology, control technology, industrial control computer, industrial communication and network information technology to coordinate all operation points, covering all levels from the factory field equipment layer to the control layer and management. Use industrial computer to realize automatic control and human-computer interaction, provide accurate real-time data interaction, and facilitate the management and implementation of producers and operators.

For the application of automated production lines in intelligent manufacturing, Agrade specializes in providing industrial-grade storage products. Combined with the actual needs of automated production lines, Agrade introduces our industrial-grade CF card series for customers, which can be applied to production line automation, MES systems, industrial automation, chemical and spraying workshops and other applications. There are two types of abnormal power failure protection: hardware level and firmware level. The power-off process is instantaneous, but the voltage does not become zero directly, but has a sharp drop process. Without adding a protective capacitor, the solid-state drive can also monitor the power supply situation through a customized version of the main control or an independent voltage monitoring chip. Once a voltage drop occurs, it will trigger a power-off protection emergency mechanism within milliseconds: immediately stop user data Receive and write, and immediately write the FTL mapping table and other data that are critical to the normal operation of the solid state drive into the NAND flash memory. In this way, when the power is turned on again next time, the solid-state drive does not need to face messy situations such as FTL damage and Page writing disorder.