News

电商部

电商部  2025-12-04 11:19:46

2025-12-04 11:19:46 PATA DOM vs SATA DOM: Key Differences for Industrial Storage Selection

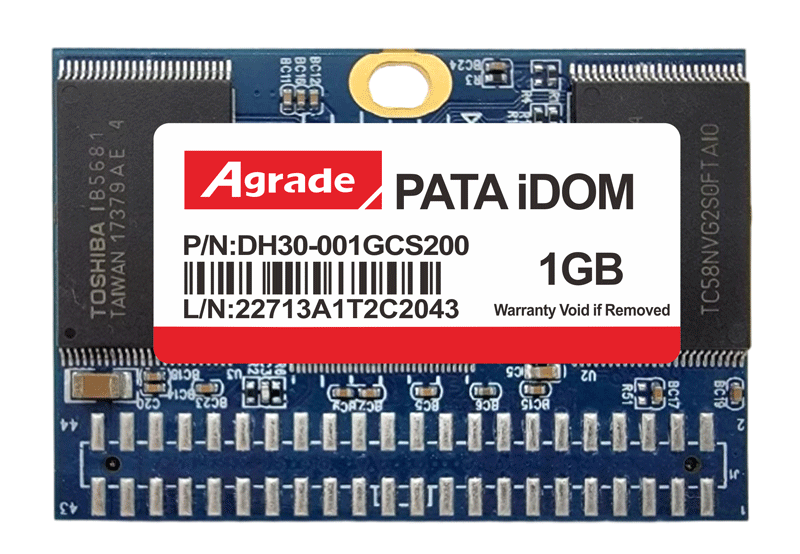

Choosing between PATA DOM and SATA DOM hinges on understanding their interface, compatibility, and performance tradeoffs—critical for industrial storage success . PATA DOM uses parallel 40pin/44pin IDE interfaces, while SATA DOM features a serial 7pin SATA connector, creating fundamental differences in legacy support and speed . For industrial systems built before the SATA era, PATA DOM is irreplaceable: it works seamlessly with older motherboards lacking SATA controllers, eliminating the need for costly hardware upgrades . SATA DOM, by contrast, excels in modern systems, offering faster transfer speeds but no backward compatibility with IDE-based industrial PCs .

Performance disparities reflect their interface designs. PATA DOM tops out at Ultra DMA Mode 4 speeds (up to 66MB/s), sufficient for boot tasks and moderate data logging in industrial automation . SATA DOM delivers sequential read speeds up to 300MB/s, ideal for data-intensive modern applications . Power consumption also differs: PATA DOM uses 5V 驱动电压 with higher 功耗,while SATA DOM’s 0.5V 低压 design reduces energy use by 30%-50% . For legacy industrial setups where compatibility trumps speed, PATA DOM is the clear choice; for new industrial projects needing faster data throughput, SATA DOM prevails .

Environmental resilience and form factor further guide selection. Both offer industrial-grade temperature ranges (-40°C to 85°C), but PATA DOM’s compact 44pin design (45×28×6.37mm) fits tighter spaces in older embedded systems . SATA DOM’s larger footprint requires more installation space, a limitation in legacy enclosures . Use cases highlight these differences: PATA DOM shines in upgrading 20-year-old textile machinery or railway signaling systems, while SATA DOM suits new smart factory setups . Ultimately, PATA DOM’s strength lies in legacy compatibility, making it indispensable for industrial environments where replacing entire systems is impractical or cost-prohibitive .