News

电商部

电商部  2025-12-05 10:20:11

2025-12-05 10:20:11 Industrial mSATA SSDs – Key Features for Embedded Systems & IoT Devices

Industrial-grade mSATA SSDs are engineered to meet the rigorous demands of embedded systems, IoT (Internet of Things) devices, industrial automation, and automotive applications—environments where consumer-grade SSDs would fail quickly due to extreme conditions, constant use, and reliability requirements. Unlike consumer SSDs, which are designed for occasional use in temperature-controlled environments, industrial mSATA SSDs are built to withstand harsh conditions while delivering consistent performance and long-term durability. Let’s break down the key features that make industrial mSATA SSDs indispensable for industrial and IoT use cases.

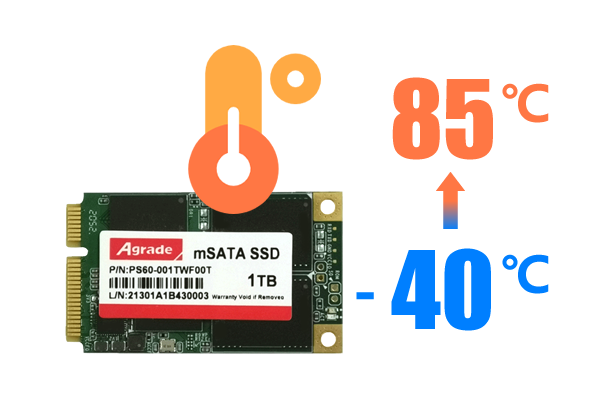

First and foremost is temperature tolerance. Consumer mSATA SSDs typically operate within a range of 0°C to 70°C, which is suitable for home or office use but inadequate for industrial settings where temperatures can drop to -40°C (in cold storage facilities or outdoor IoT sensors) or rise to 85°C (in factory control panels or automotive engine bays). Industrial mSATA SSDs are tested to operate reliably within this wide temperature range (-40°C to 85°C), using specialized components and thermal management techniques to prevent data loss or performance degradation in extreme heat or cold. This makes them ideal for applications like oil and gas monitoring, outdoor security cameras, and automotive infotainment systems.

Another critical feature is endurance, measured in TBW (Terabytes Written) and MTBF (Mean Time Between Failures). Industrial applications often involve constant read/write cycles—for example, IoT devices that log sensor data every second, or industrial controllers that process real-time data from production lines. Consumer mSATA SSDs typically offer 100-300TBW of endurance and 1M hours MTBF, but industrial models exceed these specs: top industrial mSATA SSDs offer 150-1200TBW of endurance (3x to 10x that of consumer drives) and 2M-5M hours MTBF, ensuring they can handle continuous use for 5-10 years without failure. This level of endurance is achieved through high-quality 3D TLC or QLC NAND flash, advanced wear-leveling algorithms (which distribute data writes evenly across the drive to prevent premature wear), and over-provisioning (reserving a portion of the drive’s capacity for maintenance tasks).

Security is a top priority for industrial and IoT applications, where sensitive data (like production metrics, customer information, or control system data) is often stored on the SSD. Industrial mSATA SSDs include robust security features to protect this data, such as XTS-AES 256-bit hardware encryption (which encrypts data at rest, preventing unauthorized access if the drive is stolen) and TCG Opal 2.0 compliance (a standard for self-encrypting drives that allows for secure key management and remote lock/unlock capabilities). Some models also offer secure erase functionality, which permanently deletes data from the drive—critical for compliance with regulations like GDPR, HIPAA, or ISO 27001.

Power efficiency is another key consideration for battery-powered IoT devices and remote systems (like solar-powered sensors) where power is limited. Industrial mSATA SSDs are designed to consume minimal power, with idle power consumption as low as 0.08W (compared to 0.2W-0.5W for consumer drives) and active power consumption of 1.5W-3W. This low power draw extends battery life, reduces energy costs, and minimizes heat generation—important for devices that operate in sealed enclosures.

Durability and reliability are also enhanced through features like vibration and shock resistance. Industrial environments are often noisy and prone to vibration (e.g., factory floors, construction sites), which can damage consumer SSDs over time. Industrial mSATA SSDs are tested to withstand vibration up to 20g (peak non-operating) and shock up to 1500g (operating), using reinforced casings and shock-absorbing materials to protect internal components. They also support S.M.A.R.T. (Self-Monitoring, Analysis, and Reporting Technology), which allows system administrators to monitor the drive’s health in real time (e.g., remaining endurance, temperature, error rates) and predict failures before they occur, minimizing downtime.

Top industrial mSATA SSD models include the Kingston KC600 mSATA (which offers 600TBW endurance, -40°C to 85°C temperature range, and AES 256-bit encryption), the Samsung 870 EVO m